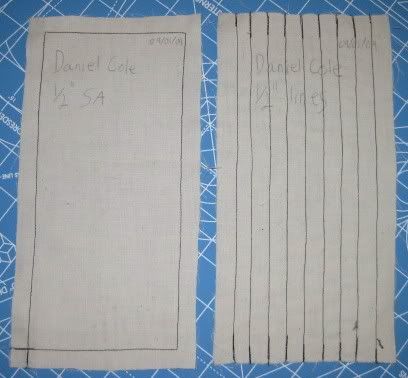

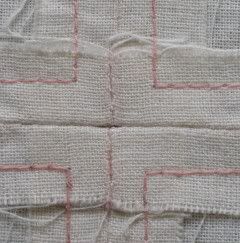

second assignment required us to line up two seams to make an intersection, and it also involved topstitching. On both assignments I lost a half point because not all of my stitching lines were perfectly straight. I lost a full point on the second assignment because my seams did not line up perfectly; they were off by less than the length of a stitch, but off is off. The instructor explained that we must be able to line up our seams perfectly. There was no partial credit for being close. Seams that lined up earned one point; ones that did not line up got no credit. I will do better next time.

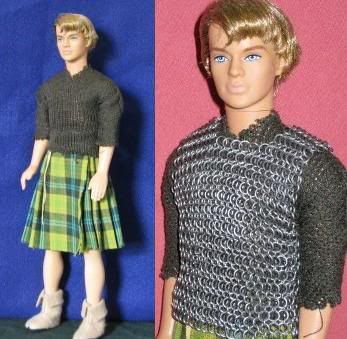

second assignment required us to line up two seams to make an intersection, and it also involved topstitching. On both assignments I lost a half point because not all of my stitching lines were perfectly straight. I lost a full point on the second assignment because my seams did not line up perfectly; they were off by less than the length of a stitch, but off is off. The instructor explained that we must be able to line up our seams perfectly. There was no partial credit for being close. Seams that lined up earned one point; ones that did not line up got no credit. I will do better next time. The topic for the day was darts. I enjoyed making darts, and I think I did it well. I expect I will earn the full five points for this assignment. It turns out I have been making darts for a few years now, and I did not know I was doing it. I use darts on the pants I make for dolls. I just thought it was a good way to make the pants fit better. I never knew there was an official name for what I was doing. I wonder what else I have been doing.

At the start of class I made sure I got a good machine. I did not want a repeat of last week. There were a few minutes left in class after I finished my assignment, and most of the machines were no longer in use, so I decided to try a few of them. I found two machines that are much better than any other one I have used. I plan to use those machines as much as I can.

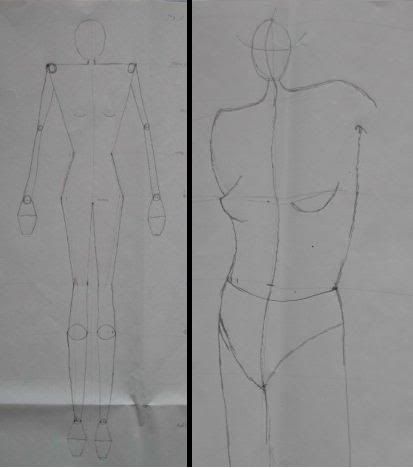

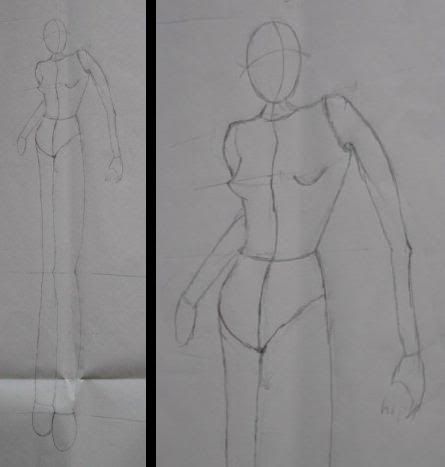

In the evening I attended my first fashion sketching class. I did not know what to expect, and I was worried that my lack of drawing skills would leave me unable to complete the class work. I need not have worried. Many of my classmates are as bereft of drawing skills as am I. We have a great instructor. Everything was explained clearly and the class was interesting and fun. This made the work a lot easier than I thought it would be, and while I still would not call it easy it was doable. By the end of the class I had produced the best human figure I have ever drawn.

The class is a non-credit continuing education course. It meets only five times. I want at least a full semester of drawing class, and I will probably need more than that, but this class is a good start. I hope to find additional drawing classes at UW-Stout, and I plan practice drawing on my own. Sewing and design skills are more important than drawing skills, but to be truly successful I will need them all.

Fashion sketches are supposed to have elongated legs, but I got a little carried away with my elongation. All aspects of my sketching need improvement, but I think I should work on legs first. I suppose that in a way it is a little encouraging to think that with my current level of skill all I can do is improve.

Fashion sketches are supposed to have elongated legs, but I got a little carried away with my elongation. All aspects of my sketching need improvement, but I think I should work on legs first. I suppose that in a way it is a little encouraging to think that with my current level of skill all I can do is improve.