Monday, December 21, 2009

The semester in review, part 2: the important stuff

Experience counts - Practice, practice, practice. What is difficult at first becomes easier over time. Sew a lot and your sewing will improve. Complicated procedures become easy with experience.

Muslin is cheap - Play around with it. Sew stuff. See what happens. Make stuff in muslin first to learn how to do it. Big mistakes in muslin are no big deal, but big mistakes with expensive fabrics may make you cry.

Sewing requires a lot of attention - If you become distracted as you sew you will probably need to rip out some stitches. Pay attention. I often listen to my iPod as I sew. Classmates are more distracting that music.

Mistakes happen; it's OK - My seam ripper may be my most important tool. I tell myself that every mistake is a learning experience. It is a good idea to have some extra fabric. Remaking a small piece is sometimes easier and less time consuming than ripping out stitches.

Sergers can screw you - A mistake on a serger can cut your fabric. Stitches sewn in error can be torn out, but cut fabric may be beyond repair. A lockstitch can put a needle through a finger; a serger can cut off a finger tip. Sergers are fun, but please be careful.

Don't sew angry - Sewing angry as just as bad as sewing distracted. Relax. If I make a small mistake I deal with it and keep going. If I make a big mistake, or if I continuously make the same small mistake, I will stop work and take a small break. I leave the lab and eat a bag of Skittles. After I calm down I can think about what I learned from my mistakes, and hopefully they will not be repeated.

Press everything - Press your fabric before tracing your pattern pieces, after you cut them out, and again before you sew. Press open seams as soon as you finish sewing them. Press everything, then do it again. This brings us to my next point...

Irons are hot - We all know this, but it still needs to be mentioned. Be careful, but no matter how careful you are you will still occasionally singe your finger tips. First degree burns are part of sewing. Stop complaining and just deal with it.

Industrial machines are fast - I learned to sew on a home machine. At the start of the semester industrial machines intimidated me, but now I love them. I need a lot more practice, but I will eventually become adept.

Work at your own pace - We have deadlines to meet, but if you go too fast you may screw up. It is better to spend a few extra seconds sewing slowly than minutes making repairs.

Machines have personalities - I am not referring to the differences between different makes and models. Every machine is different. Find one you like and try to use it as much as you can. I used a few Juki DDL 5530N machines at school. One of them is my favorite machine in the lab, one I hate, and the rest are OK. If you are using a machine for the first time you should spend a few minutes getting used to it.

Sew on a piece of scrap first - Before starting work you should test your machine on a piece of scrap fabric. The machine may not be threaded correctly, the tension may be off, and there may be other problems. The scrap should be the same type of fabric that you will be using.

Watch your bobbin - No matter how much thread you think you have on your bobbin you really have less. It is not fun to have a bobbin run out of thread halfway through a seam.

Help your classmates - Maybe someday you will be on Project Runway, but until that day comes you should not think of sewing as a competition. We are all in this together. All of us need help at times. Today you help a classmate and tomorrow someone helps you. Play nice.

Watch your tools - Share your tools and supplies with your classmates. Sooner or later you will need to borrow something from one of them. But keep an eye on your stuff. You will spend a lot of money on equipment; try to not lose things. This semester I had to replace a clipper, a seam ripper, and two rulers. They were not stolen, I just left them behind. Write your name on your stuff.

Pins are your friend - There is no such thing as too many pins. Difficult seams become simple with lots of pins. It is easy and quite tempting to sew over pins, but you should not do it. You can usually get away with it, but the first time your needle hits a pin you will understand. Keep the pins away from the seam line if you are using a serger.

Don't give up - Some things are easy, some are not. Ask questions, seek help, and keep trying. Even the most difficult tasks become easier with experience.

Sewing is fun - You should enjoy what you do. You need to love sewing in order to devote enough time to it to become proficient. If you hate to sew this might not be the right career path for you. Perhaps you are better suited for a different area in the fashion industry, or perhaps a different industry entirely would be best for you. Fortunately I find sewing to be exhilarating and enjoyable.

I learned a lot of other things too, but these were the ones that came to mind as I wrote this blog entry. The two most important pieces of knowledge I gleaned are the first and last ones mentioned: Experience counts and sewing is fun. Tasks that at the start of the semester seemed impossible are now easy. I am confident that as I take more classes my skills will continue to improve. This was one of the most the most enjoyable classes I have ever taken, and I am excitedly looking forward to my future in fashion.

Tuesday, December 15, 2009

I finished my shirt

Despite all the problems, I am very pleased with my shirt. I learned a lot. My next shirt will be a lot better. My goal was to learn how to make a shirt, not to make a great one. I will need a lot more experience making shirts before I can make great ones, but I think I am off to a good start.

Monday, December 14, 2009

The semester in review, part 1: Sewing lessons

1. Define lengthwise and crosswise grain. I grew up in New York. So what does that have to do with grainlines? I have lived in flyover states for the past 15 years, but I still think of myself as a New Yorker, and view grainlines with a New York perspective. Avenues are on the lengthwise grain (wrap), streets are on the crosswise grain (weft), and, as my grandfather was wont to say, Broadway is on the bias. The Hudson and East Rivers are the selvage. I like working with bias cut pieces; they make me think of Grandpa.

2. How do you find the true bias on your fabric? The true bias is at a 45 degree angle to the the lengthwise and crosswise grains. Fabric stretches the most at this angle.

3. Define ease. Room for movement. A little extra measurement.

4. How do you correct bad tension on your sewing machine? Test your machine on a scrap piece of fabric. Turn the tension know one way or the other until the tension is good.

5. What is the purpose of darts? Darts add shape to garments. They fit a two dimensional piece of fabric to a three dimensional body.

6. How do you know a pattern piece is on the straight of grain? Measure from the edge of the fabric.

7. What are the most common seam allowances used in industry? 1/2", 1/4", and 3/8".

8. Why is accurate cutting important? If you do not cut your pieces accurately they may not line up right. Fabric is expensive and we do not want to waste it.

9. Why is it necessary to press after each sewing step? Seams must be pressed so that they will be flat.

10. Define the difference between a 4 and 5 thread serger. The 5 thread seam is stronger than the 4 thread one. The 4 thread seam is stretchier. Both machines can be used for a 3 thread seam which is weaker and stretchier than the others.

11. What is the difference between topstitching and edgestitching? Edgestitching is very close to a seam or edge of the fabric. Top stitching is (often) 1/4" from a seam or edge of the fabric. The distance from the needle to the edge of the presser foot is 1/4". both topstitching and edgestitching are on the right side of the fabric. They can be decorative, functional, or both.

12. What is the purpose of interfacing? It makes fabric firmer and less stretchy.

13. What factors influence the type of interfacing you use in garments? The type and weight of the fabric. How firm I want the fabric to be.

14. How do you recognize the front and back of sleeve patterns? The front has one notch, the back has two.

15. What is the most common setting for stitch length? 10-12 stitches per inch. The stitch length know on industrial machines is set between 2 and 3. At least that is the stitch length we used in class. The machines can be set for bigger and smaller stitches, but I have not yet learned about them. I do know that long stitches are used with leather. I do not know about the shorter stitches yet. I have a lot more learning to do.

16. Define Vicki's golden sewing rule. Vicki is my instructor. Her golden sewing rule is, "Right sides together when stitching a seam. OK, Vicki was not the the first one to say this, but it is an important rule. There are are a few occasions when we do not obey this rule, but they are rare.

I learned a lot more this semester than what is listed above. The main focus of the class was learning how to sew with industrial machines. I will address that along with some of the other things I learned in part 2 of my semester review.

Tuesday, December 1, 2009

My clothing is changing me

As I was on my way home from work yesterday I noticed Macy's had new window displays. Before this semester it is unlikely I would have noticed this, but even if I had noticed I would not have cared. Last night I spent more than 20 minutes looking through Macy's windows. After leaving Macy's I went north a few blocks to look at Saks and Neiman Marcus. Saks had no clothing in its window displays; there were just posters promising large savings. It is an Off 5th Saks Outlet so I understand the promise of savings, but I still expected to see some clothing on display. I have never paid much attention to Saks before so I do not know if this lack of displays is normal. There were dresses on display at Neiman Marcus - not as many as at Macy's, but I thought the Neiman Marcus dresses were much nicer than the Macy's ones. It is nice to know that I have good taste.

This change in my attitude towards clothing struck me quite hard a few days ago at work. As one of my coworkers and I were sitting at the front desk a beautiful woman walked through the lobby. After she exited the building my coworker and I looked at each other and smiled. I suddenly realized I had been thinking about her dress while he was thinking about something else entirely. If he thought about her dress at all it was to think how nice it would look crumpled up on his bedroom floor the next morning. In retrospect I realized that my bedroom floor is where I would most like to see that dress with my attention devoted to its owner, but I would like to devote a few minutes after breakfast to the dress too. It is a little scary how much my attitudes have changed in just one semester. What will I be like in three or four years?

Friday, November 27, 2009

Another shirt and some thoughts about prints

This shirt is 100% cotton which is much better than the polyester I used before. What little experience I gained from the first shirt helped a lot with this one. At this rate of improvement I should have a nice shirt finished by the end of my fourth or fifth attempt. The biggest improvement with this shirt was the seams. The seams on my first shirt were unfinished; on the second shirt I made flat felled seams for the shoulders, sleeves, and sides. My stitching could have been straighter, but I am still quite pleased with my seams.

There are three problems with this shirt, two of which I should be able to overcome with the next one. The buttonholes are a little too big, I screwed up the collar, and the shirt is the wrong size. All three problems provided learning experiences so I am not too upset. I now have a better understanding of how to correctly size button holes. The collar was the most difficult part of the shirt. It needed a few attempts to get it attached and I never got it on well, but by the time I was done I finally understood how this type of collar works. The next one will be easy. As for the size of the shirt, unless I want to get another pattern there is not much I can do. I do not yet feel comfortable enough to try resizing an existing pattern. I wear large shirts, so I thought I should use the same size pattern. I should have used medium. I do not know if all patterns are sized too big or if it was just this one. I will know more about sizes after I try a different pattern.

Before beginning work on the shirt I went to Walmart to buy the fabric. I picked a nice print with flowers, but before I got to the cutting counter I found a bolt of the black and white striped print. The flower print was a lot nicer, but the striped one was only $1.00 per yard. Economy trumped aesthetics. I will hold off using nicer (and more expensive) prints until I can make a shirt I want to wear. As I was loading the fabric into a washing machine I discovered a copyright message in the selvage.

I understand taking out a copyright on an intricate design with lots of shapes and colors, one with flowers, or one with copyrighted characters. Perhaps even an original plaid or an intricate striped design with multiple colors and stripe widths deserves a copyright. But simple black and white stripes? Is this pattern truly worthy of copyright protection? Surely someone used black and white stripes before MBT. What obligations do I have if I use a copyrighted pattern? Do I need to give MBT credit for my shirt? Can they sue me if my shirt is not up to their high standards? Maybe I should just use solid colors. Does anyone hold the copyright for red?

And now for the obligatory class update: On Tuesday I made but did not attach the collar for my tailored shirt. Unlike the collars on the shirts I made at home, this one has a neck band. Now I know how to make two types of shirt collars. I also finished the front placket and attached the two front pieces to the back. This shirt has a yoke while the two I made at home do not. It took me a few minutes to figure out how to put the pieces together, but after I got them pinned the sewing was easy. I will either alter the pattern I am using at home to include a yoke or find a new pattern that already has one. I have two class sessions left in which I must attach the collar, make and attach the sleeves, close the sides, and hem the bottom. It is a lot to do, but I am on schedule and I have confidence in my ability to turn in a well made shirt on time. Then all I will need to worry about is my final exam.

Saturday, November 21, 2009

UW-Stout transfer student orientation

Transfer student orientation at UW-Stout is a streamlined and painless affair. There was only one speaker and she only discussed topics that were relevant and necessary for everyone. She told us how to access our online student accounts, how to get a student ID card, and how to register for classes. We signed up for laptop pick-up times, and we received info about textbook rental. (Tuition includes fees for laptop and textbook rental. More about that after the semester starts.) Rather than addressing every possible concern that a new student might have she gave us a form listing the most common concerns and the departments to speak to about them. We were in and out in just a little over one hour.

After the speaker finished I had ninety minutes to kill before my appointment with my advisor. I had my photo taken for my ID card, ate my lunch, and wandered around campus. I was thrilled to see the campus has a disc golf course, but the holes seem awfully close together. I will need to play the course a few times before I can decide if it is any good. I was surprised by how few squirrels I saw around campus. Stout does not have a culinary arts department, so I do not know where all the squirrels have gone. Squirrels are an integral part of any college campus. I will start feeding the squirrels after classes begin in an effort to help bolster their numbers.

Two thirty finally rolled around and I met with my advisor to discuss what classes I will take next semester. I am transferring in with more than 60 credits, and not one of those credits is in apparel design. I am able to apply some of those credits to most of my out of major requirements, so I may be able to finish in three years instead of four. My speech, economics, math, history, and lab science requirements are already fulfilled as are most of my general education credit requirements.

After meeting with my advisor I went to register for classes. I will have a full class load – five classes for 15 credits. Monday, Wednesday, and Friday will be busy days. I will have class from nine to two thirty with an hour off for lunch. Tuesdays and Thursdays are easy with a three hour block of classes in the afternoon.

I registered for three apparel design classes and two out of major requirements. I will be taking the following classes:

APRL 145 – Interior Decorating/Design Textiles This is the same as APRL140 – Textiles, but I could not fit that section of the class into my schedule. Interior design students come to the apparel design department to learn about textiles. The Interior Design department requires its students to take classes with “interior design” in the title. The Apparel Design department understands that it is the content of a class, not its name that matters.

APRL166 – Apparel Construction This is the introductory sewing class. We will learn about machine use, various types of seams, and sewing terminology. We finish by making a tailored shirt. I could have tested out of this class, but I think I will benefit from taking it.

APRL274 – Fashion Industry This class is about the fashion industry. It is recommended for third semester apparel design students, but it has no prerequisites and I could fit it in my schedule, so I decided to take it now. My hope is that this class will help me decide what specifically I want to do in the apparel/fashion industry so that I can structure my future classes around that decision.

SOC110 – Introductory Sociology This class is required for my major. I am not looking forward to it but there is no avoiding it. I will get it out of the way as quickly as possible.

ENG101 – Freshman English-Composition This is another unfortunate requirement that I must take. I am not able to register for this class yet. I must first prove that I posses basic English language skills either with a recent ACT score or by passing a placement test. I took the SAT in 1992, but Stout demands an ACT taken within the past three years. So 12 days from now I head back to Menomonie to take the placement test. Me ain’t frettin’ none. Me does rite english goodly.

Tuesday, November 17, 2009

One ugly shirt and what I learned from it

I was going to use muslin for my first shirt, but at Walmart I found a print for three cents per yard more than the muslin. It is polyester, and the print is horribly ugly, but I had not worked with prints or polyester before so the fabric presented me with two more things to learn from this project.

Buttons and button holes - I still want to learn how to use the industrial buttonholer, but using my home machine was a lot easier than expected.

Pocket - this was the first pocket of this type I have made. All the edgestitching we have done in class this semester has paid off.

Shoulder and sleeve seams - Attaching the sleeves was easier than expected, and I am pleased with the seam finishes.

The collar - This was my first collar, and I did not do a good job with it. I made a few mistakes as I attached the collar. The pattern was confusing, but I accept the full blame for the problems. My next one will be better.

Sleeve and bottom hems - The hems did not turn out well. I know I can do better.

The loop - The pattern called for this loop. I made it well, but I do not like it. I think this loop is a silly way to fasten the top button. My future shirts will have buttonholes rather than loops.

Pattern pieces - I began work by transferring the pattern from pattern paper to oak tag. I then used my oak tag pattern to trace the pieces on fabric. With each step there is a slight margin of error. As I pinned together the pieces of fabric I found my notches did not always line up perfectly. Precision is necessary.

What I learned

Buttons and buttonholes - These were the first buttonholes I made with my current sewing machine. With other machines I found making buttonholes a very difficult process, but this time it was easy. It was the first time I used a buttonhole presser foot. I do not know why I did not learn how to use a buttonhole foot in my seventh grade home economics class. As I was reading my machine's user manual to learn how to use the buttonhole foot I discovered that I also have a presser foot for attaching buttons. I did not know that I could use a cheap home machine to attach buttons; I have always sewn on buttons by hand. It was much easier with the machine, and the machine did it better than I can do by hand. The lesson: read your machine's user manual.

Polyester - Ironing shrinks polyester. It shrinks as I press seams, and it shrinks a lot more as I attach fusible interfacing. If I iron over a pin I will leave a burn mark in the fabric. Removing stitching from polyester can be difficult. Tearing or stretching the fabric while removing stitching is easy. The lesson: do not use polyester if other materials are available.

General stuff - Making this shirt helped me understand how tailored shirts are constructed. Knowing that I already made one shirt, even a bod one, gave a boost to my confidence as I worked on the shirt in class today. Some of the other students were nervous about attaching their pockets, but I knew I could do it because I attached a pocket yesterday. The lesson: sew a lot. Then sew some more. Practice, practice, practice. Experience counts.

Tuesday, November 10, 2009

The shirt begins

I sewed four darts and attached the yoke to the back today. Darts are simple, the yoke was just a simple seam, and there is nothing particularly complicated about a tailored shirt, but this is the first semester of my first year as an apparel design student so cut me some slack. In a year or two a tailored shirt will be the sort of simple project I will make to pass time on a Sunday afternoon, but for now this is a big and exciting project.

The sewing was easy today, but there was a little excitement too. I thought I had cut all the pieces last week, but it turns out I missed a few. I began class by cutting out the remaining pieces. After I finished sewing he darts i realized that I was not sure if I used the large or medium pattern last week. I had sewn darts on one piece cut last week and two pieces cut today. I ran around the room collecting pattern pieces to check my sizes. If I used the wrong size pieces today I would have had to redo my work, but fortunately my pieces were all the same size. It was just good luck that I did not have to redo my the pieces, but I learned an important lesson from this: I must pay attention to what I do, and I must keep a record of what I have done for projects that take more than one day.

Despite my progress on the shirt and the happy ending to the day's excitement, class ended on a sad note. I asked my instructor when we would learn how to use the buttonholer, ans she told me that we will not. She explained that the machine is expensive, difficult to use, and easy to damage. She added that in the past students have caused the machine to require thousands of dollars of repairs. First semester students are no longer permitted to use the machine. After we finish our shirts our instructor will add the holes. I was looking forward to learning how to use the machine. I want to know how to use as many different machines as possible, but I have a second reason for wanting to know how to use this particular machine. I do not like making buttonholes on my home machine. Before the end of the semester I wanted to use the industrial buttonholer to make a few hundred holes to hake home with me so that any time I need a hole I would have one available. I still need to work out a few details of this plan, but I want to eventually complement my jar of buttons with a matching jar of holes.

Sunday, November 8, 2009

Pattern, pattern, pattern

I have made vests before but never with so many problems. My other vests I either designed myself or were based on simple patterns I found online, while now I am using a Simplicity pattern. This vest is more complicated than my previous ones, but my problems seem to be caused by the pattern itself and not the act of sewing. The sewing would itself would be easy if I could figure out what to do. The instructions make no sense. A picture is provided for each step, but the step 2 instructions seem to correlate with the pictures for steps 1 and 3, and it just gets worse from there. Instructions for the side and back seams are repeated in a few steps while only partial instructions are given for the bottom and neck pieces.

No doubt my lack of experience with patterns accounts for some of my woes, but I think this particular pattern deserves the lion’s share of the blame. The jacket was much more complicated than this vest but making it seemed a lot easier.

My plan was to make two copies of this vest strictly adhering to the pattern, one in muslin to learn how to make it and one with fashion fabric to wear. If I liked the general look and shape of the finished piece I would then make one or two more vests with modifications of my own design. I will finish the muslin vest, but I may then move directly to a modified design. If I ever have a finished vest that I am not ashamed of I will post a picture of it here.

Thank you for taking the time to read my long winded and self pitying rant. I will try to keep my future posts more positive. The past few days have been stressful, and I needed this chance to vent my spleen. I suppose I could start smoking, but kvetching to strangers online seems a little more productive and a lot less unhealthy.

Tuesday, November 3, 2009

T-shirts

The baby t was the first shirt we made. Everyone in class agreed that of the two it was the more difficult one. I do not know if that is because it is smaller or because by the time we started work on the adult t we had more experience with sergers.

It took me three attempts to make the baby t. Fortunately I had finished my previous assignment early so I had time to cut out multiple copies of the pattern pieces before the class began work on the shirts. My first attempt was a dismal failure, but it provided useful experience with sergers. The shoulder seams were easy, but after multiple attempts and failures to attach a sleeve, the fabric had been trimmed too much for me to continue. I used what I had already assembled as scrap. It would have been nice to finish a shirt on my first attempt, but I was neither surprised nor upset with the outcome. I began that first shirt knowing it was just practice. By the time I gave up on it I felt I had finally figured out how to successfully attach a sleeve, and I learned a trick that proved invaluable on all my following shirts. I found it to be a lot easier to attach sleeves and neck ribbing if I used two different color fabrics. This allows me to see exactly where the two pieces of fabric are so I am able to sew the seams without any holes.

Before I began work on shirt number two the instructor made one to show the class how to do it. It took her no more than ten minutes, and she was working slowly so that she could explain each step along the way. I spent nearly 90 minutes working on my shirt. The neck ribbing was the most difficult and time consuming part, and while I managed to attach both sleeves on the first attempt without any problems the process was also quite difficult. I had not yet learned how to use the coverstitch machine, so for the bottom I did a mock coverstitch hem with the serger and a straight stitch. Unfortunately, as I was using the serger my hands slipped and I gouged a large chunk out of the shirt. I knew I would not be able to turn it in, but I finished it anyway. It was still good practice, and I was doing fine on time.

I do not know any babies, but my teddy bear was willing to model the shirt for you. It is a little big on him, but at least I do not have to worry about him outgrowing it.

Attempt Number three was a lot easier. I finished the shirt in about one hour. I knew what I needed to do, and I was sewing with a little confidence. I knew the shirt was not perfect, but I was pleased with it and I wanted to give one of my classmates time on the serger. There are 20 students in the class and only nine sergers. I lost one point because one of my shoulder seams was not perfect, one point because the neck ribbing was not perfectly centered, two points because the armpit seams did not line up perfectly, and two points because the bottom hem was not perfectly straight.

The adult t-shirt was the easiest one yet. It took me less than 45 minutes to make. The only men's pattern was for a v-neck shirt, and I do not like v-neck shirts, so I made a women's shirt. I will give it to my sister. The pattern called for the sleeves to be hemmed with the coverstitch, but I thought they would look better with a ribbed cuff. I told the instructor how I felt, and she said that as long as I could make it work I could make the sleeves however I liked. I went with the cuff. My classmates were impressed with my innovation, and the instructor gave me a perfect score for the sleeves. The total grade consisted of eight sections, each with a maximum score of five points. I lost one point for a shoulder seam and two points for the armpit seams.

It did not change my final score, but I was thrilled to see that for the neck ribbing and serger use my score was five plus.

It did not change my final score, but I was thrilled to see that for the neck ribbing and serger use my score was five plus.

The semester is almost over. The only things left to do are make a tailored shirt, learn to use a button hole machine, and pass my serger threading test. I could have threaded a serger today, but I wanted to let my classmates who still needed to finish their t-shirts use the machines; I will do it next week. The instructor did not want us to start sewing the tailored shirt today. She will provide detailed instructions for it next week. I was able to cut out all my pattern pieces though, so I will be able to start work as soon as she says go. It is a big project, and I admit I am a little intimidated by it, but I think I will make a good shirt. If there is one skill everyone in class has become great at this semester it is tearing out stitching. I hope I will not have to do too much of it, but at least I can do it well.

Saturday, October 31, 2009

Homework woes

The only homework I have had this semester was to buy supplies and to cut out lots of 5" x 10" muslin rectangles. There are no homework assignments that require sewing. I would like to be able to work on my assignments outside of class, but that is not possible. My instructor does not object to students finishing assignments at home, but the work must be done on industrial machines. My only machine is a cheap home lockstitch. My last two assignments in class were done on an overlock.

More time to work on my assignments would be nice, but what I really need is more practice time on the machines. At the start of the semester industrial lockstitch machines scared the heck out of me and I had nearly no control of what I did with them. Ten weeks in and I love industrial machines. My home machine now seems slow and under powered. My sewing skills still require a lot of improvement, but I can now use industrial straight stitch, overlock, and coverstitch machines with some small amount of confidence. Most importantly, I see myself improving every time I sit down at a machine.

There is a lesson in all of this; perhaps the most important lesson of the semester. Sewing is not an innate skill, it is learned. Practice makes perfect. To become a master of my trade I must spend as much time as possible sitting at a sewing machine.

Friday, October 30, 2009

I'm in syndication

Wednesday, October 28, 2009

Menomonie, WI

I went to Menomonie to find an apartment, and oh boy did I find one. I already put down my security deposit. My new apartment is much larger and nicer than my current one, and rent will be 23% less than what I pay now. I will move January 4, 2010. Most of the tenants are Stout students. The neighborhood looks quite nice, the building is less than two miles from campus, and it is downhill all the way. My bike ride to school each morning will be fun, although the ride home will not be quite so easy. The up parts of hills are always much bigger than the down parts. I am not quite sure how that works; I will have to ask a mathematics professor about it.

I stopped by the financial aid office to discuss my upcoming financial hardships. I am not happy with the answers I received, but they were the answers I expected. I am not poor enough to get grants or subsidized loans. I can afford school, but I would much rather have Uncle Sam foot the bill.

I took some time to walk around campus and the town. I was surprised at how few students I saw on campus. Many of them would be in class, but I still expected to see more people outside. I cannot blame the weather; it was a balmy 40°F.

I like the campus, but I am still undecided about the town. My neighborhood is very nice, but I was not impressed with the area closer to the campus. A number of the stores and businesses were closed, and on every block there seemed to be at least two commercial properties with for-sale signs. I suppose one could describe the area as ripe for development, but to me it just looks old and run down. In this case perhaps the weather is to blame. It is a gloomy overcast day. I hope the neighborhood looks better in sunshine.

The Menomonie Walmart has a full service fabric department, and the employee who cut my fabric told me they plan to keep the department. I bought some interfacing (for class) and some fleece (because I cannot enter a fabric department without buying something I do not need). Walmart does not carry my preferred brands of rice and coffee, but as long as they have fabrics I can make do with other brands.

That is enough about Menomonie for now. Yesterday in class I made my adult t-shirt. The patterns were for women’s shirts, so I will not be modeling the shirt. I will post a photo after I find someone to model the shirt for me. I had a lot of fun making the shirt. Most of the work was done on an overlock, and for the bottom hem I got to use the coverstitch. I still do not know how to thread either machine, and I have not yet learned how to use all of the coverstitch’s functions, but I greatly enjoy both machines and I look forward to using them in the future. The only drawback to these machines is that the school does not have enough of them. The twenty students in my class must share nine overlocks and one coverstitch. I was the only one in class to finish the adult t-shirt, and my next project will be done on a lockstitch, so I may not get to use an overlock or coverstitch again this semester. Hopefully at Stout I will have more access to machines. But if some generous soul would like to purchase an industrial serger for me I could summon up the humility to graciously accept the gift.

Monday, October 26, 2009

UW-Stout update

The acceptance came with an offer to live in university housing and a questioner from the campus health center about my immunization history. I know I have had all my shots, but I could not find the dates for all of them. I guessed. I hope that is good enough.

My plan had been to live off campus. I never considered living in a dorm, but after receiving the offer I began to think about it. Living on campus would be very convenient, and the cost of a dorm room is comparable to the cost of a one bedroom apartment. On the other hand the double rooms are 165 square feet and the singles are smaller. I would probably be the oldest person in the dorm, and I could expect every conversation to eventually roll around to, “Hey, could you buy some beer for us?”. I read through the "Life @ Stout" brochure, gave the matter a lot of thought, and reached a decision in less than one minute. Living off campus will impose a few hardships, but I think it is the right choice. I have too much stuff and I am too old to live in a dorm.

On Wednesday I will be in Menomonie to look at a few apartments and to meet with a financial aid counselor. Orientation is on November, 20; I will meet with my advisor and register for classes then. Now I need to step up preparations for the move. I still have not canceled my dentist appointment in April. I did at least get my acceptance celebrations out of the way. I had a pint of Guinness – it seemed appropriate.

Wednesday, October 21, 2009

Lunch break and a trip to Pig’s Eye

Campus was always very crowded at the start of this semester. There were long lines in the cafeteria and at the coffee shop, and open seats in the lobbies were hard to find. Now seats are always available, and even at lunch time the lines are never long. Where have all the students gone? Have they dropped out, or are they just managing their time better so that they do not need to sit in the lobbies for hours? Maybe they are all in the library studying. I have not needed to go to the school library; maybe I will visit it next week.

I bring lunch with me to school – usually a peanut butter and jelly sandwich and a bag of Skittles. I have not yet purchased anything from the cafeteria, but last week I looked at their menu. Hamburgers cost $2.25 while veggie burgers are $4.10. To produce one pound of meat a cow must eat somewhere from eight to forty pound of feed. (PETA will give you the higher numbers; the cattle industry will use the smaller numbers in response to PETA and the larger numbers for tax purposes.) I understand that there is a much greater demand for hamburgers than for veggie burgers, but the difference in price still strikes me as a little extreme. I will continue to brown-bag it.

My school has a basketball team. I have never been to a game and I have no plans to ever go to one. I do not even know where they play. I have never been a fan of college sports, and my current school has not inspired in me any feelings of college pride and loyalty. This in no way means that I object to my school having a basketball team. On the contrary, I think having a team is a good thing for this school. Even if I do not care about college basketball other people clearly do, and they should have the opportunity to play (if they play) or attend games (if that is what they like doing). So I was very upset to learn that this year will be the final year for basketball at MCTC. I understand that state budget cuts are affecting all public schools, and that basketball is not as important as academics, but I think it is still important enough that it ought to be kept. Maybe the school could raise the price of hamburgers. It is sad that the program had to be canceled to make me care about it. Last year the team’s record was 33-2. I hope their final year is just as good. I do not know what the team’s name is, but GO THEM!

Last year ten apparel design students at MCTC made outfits to be shown at the school’s Diva Project Fashion Show. The ten outfits were recently on display at Metro State University in St. Paul. I do not know why this display was in St. Paul at a school that does not have an apparel design program, but St. Paul is where they were so across the river I went. I found the outfits both daunting and inspiring. They were well made and the designers used a number of techniques that I have not yet learned. The students who made these outfits are only two years ahead of me in school. It is a little scary to think of how much I need to learn, but the thought that in two years I will be able to make outfits like these fills me with hope and confidence. The apparel construction impressed me, but the design and styles did not. Of the ten outfits on display I thought seven were quite unattractive. The remaining three were no better than OK. With most of the outfits I thought the designers got carried away adding too many features. The three I thought were OK could all have been very nice if their designers had not added so many bells and whistles. This is a problem I have noticed with a lot of student designs. The designers make the items far more complicated than needed. I have not yet designed any pieces for school, so I do not know if the overly designed garments are what teachers want or if most students just do not know where to stop. The outfits brought to mind a line from A Chorus Line, “Different is nice, but it sure isn’t pretty.” I feel the purpose of fashion clothing is to draw notice to the person wearing it, not to the clothing itself. I could be wrong about all this though; perhaps I just have a lousy sense of style. We will see what happens after I start designing clothing instead of working from patterns.

Wow. For someone who had nothing to say I certainly rambled on. I have some news about my UW-Stout saga, but I do not want to take up any more of your precious time. I will be back in a day or two with the Stout update.

Sunday, October 18, 2009

Spaghetti, seams, toilet paper, and career plans

I closely examined a few shirts to see how they were constructed. In class I have learned to use straight stitch and overlock machines, and we have discussed cover stitch machines. I was able to identify all the stitches and seams I saw today, although there are a number of them I do not yet know how to make. I do not know if I will use the cover stitch this semester, but I hope I do. Every garment I saw today had at least one seam or hem done with a cover stitch. I suppose it may look a little odd for me to be devoting attention to the wrong side of women’s shirts; I hope nobody noticed me.

In addition to garment construction I also looked at the styles and designs available. I was not impressed. I am not saying I could do better; I cannot – yet. I just do not think that the apparel offered by Target is particularly attractive. The building in which I work is across the street from Target’s corporate headquarters, and more than half the office space in my building is leased to Target. I am consistently amused to note that hardly any corporate Target employees wear clothing from Target. It is reassuring to see that Target’s employees share my view of their company's clothing, although obviously there are a lot of people who like these styles. In a five block stretch of Nicollet Ave. in downtown Minneapolis one can find Target, Macy’s, Neiman Marcus, and Saks. I see people shopping at Macy’s, but I would never describe the store as crowded. Neiman Marcus and Saks usually seem empty. Target is always busy.

Like every other design student I dream of being the next big-name designer with a line at Saks, but I do not know if that is possible. I also wonder if it is a smart goal to have. How many $40 dresses does Target sell for every $400 dress at Macy’s or $4,000 dress at Saks? Where is the larger profit, one $4,000 dress, ten $400 dresses, or one hundred $40 dresses? How much of that goes to the designer? Target clothing is designed by committee, but all the designers on that committee have a good job with a regular and decent paycheck. Jobs at Target and other similar companies are open to recent design school graduates. Designers with products at Saks must first spend years building a name and reputation. For every designer with a dress at Saks there are hundreds working at Starbucks during the day and designing on their own time at night.

It is far too early for me to early for me to make decisions about my career plans – I have not yet even started at UW-Stout – but it is never too early to start thinking about these things. I would love to be rich and famous, but not being poor and unemployed is what matters most. A good job doing something I enjoy would be enough for me, but I will never stop dreaming of greatness. I have a few years to decide what I want to do. I hope that by the time I finish at Stout I will have some better answers. For now I will just keep sewing and dreaming.

Wednesday, October 14, 2009

Sergers and sketching

In sewing class we continued working with the overlock machines. We began work on our first piece of apparel, a baby t-shirt. The instructor began class by demonstrating how to make the shirt. It took her less than ten minutes, and her shirt was perfect. It took me more than one hour, and my shirt was far from perfect. The neck ribbing is not centered, there is a small hole in one of the seams, and the bottom hem is not straight. But none of that matters. This shirt was just practice; I will make another one next week and that one will be perfect. I learned a lot about sergers while working on the shirt. They are more difficult to use than I first thought, but not so difficult that I will not be able to master them. I have a lot of fun with the sergers and I look forward to spending more time with them. I was the only person in the class to finish a t-shirt, even a bad one. I know this is not a competition – Project Runway is many years away for me – but it still made me smile.

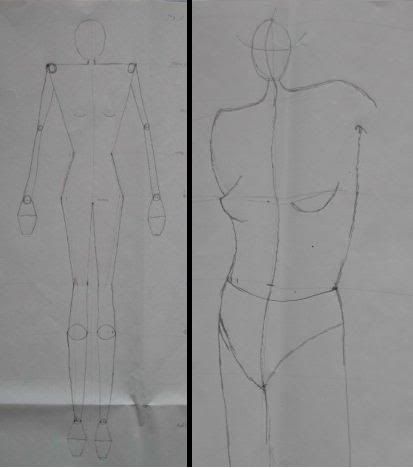

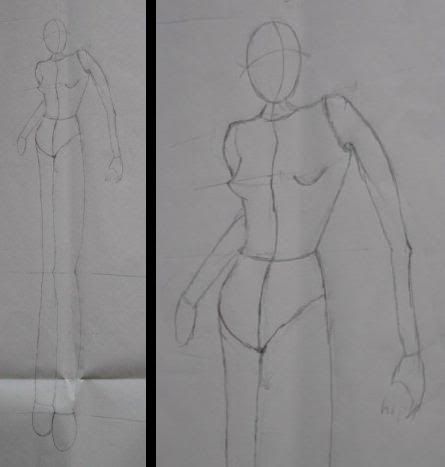

The sketching class is extremely difficult for me. I often become quite frustrated as I struggle to draw, but on those rare occasions when a drawing turns out well I am overjoyed. Last week in class we worked on faces. They are not easy, but that is OK. I am studying to be a designer, not a plastic surgeon. A good figure with a crudely drawn face or no face at all can be used to show clothing, but a great face without a good body does nothing for me. For now I will devote my attention to bodies.

At the end of class last week we watched a video about a fashion illustrator. I was amazed by how easy he made it look. Just a few swipes of a pen and he had a perfectly drawn figure in a beautiful dress on the paper. It was interesting to watch, but I found it intimidating and depressing. I know I will never be able to draw anywhere near that well. For a few days I worried about what I saw, but then I had a revelation. This man is a fashion illustrator, not a designer. Designers send him photos or rough sketches of what they made, and he produces the final sketches. I would like to see him try to make a t-shirt. Someday I will have an illustrator working for me.

My homework from last week was to find poses I like in fashion magazines and try to sketch them. I tried, and failed miserably. I was not looking forward to class. But as we started drawing all my fears melted away. Suddenly I was able to draw – not very well, but my work was good enough for now and it is a lot better that anything I could have done three weeks ago. Skills I do not posses while I try to draw at home suddenly manifest in the presence of the instructor.

We drew a couple figures and began to put clothing on them. The instructor designed the skirt on the left, and the outfit on the right is my own design. It is a very simple design and not very original, but it is all my own so I am very happy with it. I was thrilled that the instructor immediately recognized the skirt as a wrap around. Perhaps one day I will make this outfit.

We drew a couple figures and began to put clothing on them. The instructor designed the skirt on the left, and the outfit on the right is my own design. It is a very simple design and not very original, but it is all my own so I am very happy with it. I was thrilled that the instructor immediately recognized the skirt as a wrap around. Perhaps one day I will make this outfit.Thursday, October 8, 2009

Today is not so good

Could yesterday’s admission have been a computer glitch? I knew yesterday’s surcease from worry would not last forever, but I expected it to be longer than this. I needed something to cheer me up, so I went to JoAnn Fabrics and bought some notions. I will sew something tomorrow.

Wednesday, October 7, 2009

Today is a good day

I WAS ACCEPTED TO UW-STOUT TODAY!!!

I have been checking my Stout account almost daily for the past few months, and today I finally got the good news. I promptly accepted their offer of admission. In late August I received a verbal confirmation that I would be accepted, but I needed to see it in writing to allay my fears. Now I cannot stop smiling.

For the next few months I will be quite busy as I prepare to move to Wisconsin and get ready for school. This morning I made an appointment for a dental cleaning in April; now I have to cancel it. I have a lot of work ahead of me, but it will all be worth it. The nervousness should kick in soon, but for now I am just too happy and excited to worry.

Next week I will get back to my regular musings about classes and sewing, but I do have one quick statement about overlock machines now: I love them. If anyone is thinking about buying me a gift to celebrate my acceptance to Stout, a Juki industrial serger would be very nice.

Wednesday, September 30, 2009

Darts and drawing

second assignment required us to line up two seams to make an intersection, and it also involved topstitching. On both assignments I lost a half point because not all of my stitching lines were perfectly straight. I lost a full point on the second assignment because my seams did not line up perfectly; they were off by less than the length of a stitch, but off is off. The instructor explained that we must be able to line up our seams perfectly. There was no partial credit for being close. Seams that lined up earned one point; ones that did not line up got no credit. I will do better next time.

second assignment required us to line up two seams to make an intersection, and it also involved topstitching. On both assignments I lost a half point because not all of my stitching lines were perfectly straight. I lost a full point on the second assignment because my seams did not line up perfectly; they were off by less than the length of a stitch, but off is off. The instructor explained that we must be able to line up our seams perfectly. There was no partial credit for being close. Seams that lined up earned one point; ones that did not line up got no credit. I will do better next time. The topic for the day was darts. I enjoyed making darts, and I think I did it well. I expect I will earn the full five points for this assignment. It turns out I have been making darts for a few years now, and I did not know I was doing it. I use darts on the pants I make for dolls. I just thought it was a good way to make the pants fit better. I never knew there was an official name for what I was doing. I wonder what else I have been doing.

At the start of class I made sure I got a good machine. I did not want a repeat of last week. There were a few minutes left in class after I finished my assignment, and most of the machines were no longer in use, so I decided to try a few of them. I found two machines that are much better than any other one I have used. I plan to use those machines as much as I can.

In the evening I attended my first fashion sketching class. I did not know what to expect, and I was worried that my lack of drawing skills would leave me unable to complete the class work. I need not have worried. Many of my classmates are as bereft of drawing skills as am I. We have a great instructor. Everything was explained clearly and the class was interesting and fun. This made the work a lot easier than I thought it would be, and while I still would not call it easy it was doable. By the end of the class I had produced the best human figure I have ever drawn.

The class is a non-credit continuing education course. It meets only five times. I want at least a full semester of drawing class, and I will probably need more than that, but this class is a good start. I hope to find additional drawing classes at UW-Stout, and I plan practice drawing on my own. Sewing and design skills are more important than drawing skills, but to be truly successful I will need them all.

Fashion sketches are supposed to have elongated legs, but I got a little carried away with my elongation. All aspects of my sketching need improvement, but I think I should work on legs first. I suppose that in a way it is a little encouraging to think that with my current level of skill all I can do is improve.

Fashion sketches are supposed to have elongated legs, but I got a little carried away with my elongation. All aspects of my sketching need improvement, but I think I should work on legs first. I suppose that in a way it is a little encouraging to think that with my current level of skill all I can do is improve.Friday, September 25, 2009

The September Issue

The movie is playing at only two theaters in the Twin Cities. I chose the one that is closest to my home. I had never been to that neighborhood before. I knew it is in a more affluent part of town, but I did not know how affluent that area is. I saw some very nice houses on my way to the theater. Like most upper middle class neighborhoods, this one has narrow winding streets with lots of traffic lights and stop signs, so the traffic was horrible. I guess those who own a Lexus, BMW, or other luxury cars prefer to drive slowly so that others may see them and know how successful they are. I felt out of place in my Saturn. Upon finding the theater I learned it is in what seems to be a fashion district. For a three block stretch all the stores seem to be upscale apparel stores, boutiques, and jewelry stores. I got there early so I had time to window shop. I saw a number of pieces I liked, and I got a few ideas for items I want to make. I am not ready to attempt them yet, but I hope to be by the end of this semester.

This week is MNfashion Week. There are many events going on throughout the Twin Cities, and I plan to attend a couple of them. But had I known what event was going on in that neighborhood I would have gone to see the movie a different day. It was "Ladies Night Out." There were 28 people in the audience for the movie, and I was 50% of the audience's male component. Many of the shops on the street were hosting special promotions for women. I am comfortable going into an industry that is predominately female, but last night I felt quite out of place. I need to get over my lingering insecurities or at least plan my outings better.

And now on to my thoughts about the film. I regularly read Vogue and Teen Vogue. Anna Wintour is a god of the fashion world. My teachers will teach me how to design, but she will teach me what to design. And more than anyone else, it is she who decides whose designs will sell. I usually picture Mrs. Wintour sitting quietly in the front row of every fashion show, wearing large sunglasses, and displaying no emotion. It was nice, and hopefully useful, to learn something about her and how she works.

There were two non fashion related topics in the film that I found quite poignant. Every computer shown on screen in the movie was a Mac. Did Macintosh enter into some sort of agreement with the film’s producers, or is Mac the chosen computer of the fashion industry? I own two PCs. UW-Stout provides all its students with a free computer. Most students get PCs, but apparel design students are given Macs. The other non fashion topic was coffee. Mrs. Wintour is often seen with a cup of coffee. I drink a lot of coffee. In a scene in Mrs. Wintour’s kitchen a French press coffee maker can be seen on the counter. I use a French press! The knowledge that Anna Wintour and I share a preference for something, even if that something has nothing at all to do with fashion or apparel, provides me with a boost to my confidence.

I was eagerly looking forward to seeing what goes on behind the scenes at Vogue. For the most part the movie did not disappoint me, but there was one topic I felt deserved a lot more coverage. The September, 2008 issue of Vogue was a record breaking 840 pages, but only 120 of those pages were produced by the staff of Vogue. The remaining 720 pages were advertisements – six pages of ads for each page of content. The movie was about the 120 pages. While I am more interested in what went into those 120 pages, I also wanted to learn the story behind the 720.

Despite that one shortcoming I found the movie fascinating, entertaining, and often humorous. I also found it to be quite scary and intimidating. Tremendous amounts of skill and creativity are required to become a major fashion designer. I hope someday to be good enough, but it is still far too early in my career to know if I have what it takes. In addition to all that skill and creativity, designers require lots of luck to make it big. For every big name designer there are hundreds of unknown designers who are just as creative and skillful but not as lucky. I know I want to work in the apparel/fashion industry, but I have not yet progressed far enough in school to know exactly what I want to do. My schools (MCTC and UW-Stout) offer programs in apparel design, not fashion design. I do not think I want to work in high fashion, but I still dream of having something I designed on the cover of Vogue. Should I plan for a career working for an established design house or apparel company, or do I shoot for the stars? It is too early to tell, but at least I do not yet have to make the decision. Ask me again in three or four years. Hopefully by then I will have a better answer. For now I will just work on improving my skills.

Wednesday, September 23, 2009

Good machine, bad machine

We had two in-class projects yesterday. We called one a shirt and the other a skirt, but neither one is wearable. The shirt was just a piece of muslin in the shape of a shirt back to which we attached a second piece of fabric with a label. The skirt was just a big rectangle. Both pieces required edge stitching, and each piece involved one new technique for us. The shirt had a mitered corner, and we used a gathering foot for the skirt.

I knew the two projects would be more difficult than anything we had done before, so I wanted a sewing machine that would be easy to use. A few weeks ago I used a Consew 230 and was very pleased with it, so I decided to use one again. This taught me a very important lesson: it is not the make/model of machine that matters, it is the machine itself. I was at the machine for more than 90 minutes, and I spent far more time ripping out stitches and cutting new pieces than I did sewing. Eventually another machine became available, so I switched to it. It was another Consew 230, but the difference was amazing. On the first machine I was unable to sew a single acceptable seam; on the second one everything I did came out well on my first try. I used one more machine yesterday. There was only one gathering foot for the class to use. Each classroom has one machine in front that the instructors use, and that was the one to which the gathering foot was attached. I very quickly discovered why that particular machine was the one the instructors use. Of all the machines I have tried so far, that one was the easiest to use. I had no problem controlling the machine’s speed. It was almost as easy to use as is my home machine. I do not like blaming the machines for my shortcomings, but when there is so much difference in my work from one machine to the next then perhaps it really is the machine’s fault.

Next week we may start using the overlock machines. Our homework assignment is to buy the fabrics we will need for the overlocks, but I do not know if we will actually start using the machines or if the instructor just wants to make sure we all get the correct material. A few students already went shopping for it and bought the wrong stuff.

I start the Fashion Sketching class next week. It is a non-credit continuing education class, but I am still quite nervous about it. I have never possessed any drawing ability. Perhaps it is simply because I have never received any training, but I worry that I might just lack the required skills. Well, I will find out soon enough.

Tuesday, September 15, 2009

Topstitching, edgestitching, and two side projects

I have found there is often a huge difference between machines. It is not a matter of different models or brands of machines behave differently, rather each machine has its own personality. Some machines are faster or more sensitive than others. Today I chose to use the fastest machine in class. I knew there are easier machines with which to work, and that by using the one I chose I would make my work a lot more difficult, but I think that if I can become comfortable with the more difficult machines then my work with all the machines will improve. It was the machines sensitivity, not its speed that I found most daunting. I would tentatively apply a little pressure to the pedal, and nothing would happen. I would slowly apply more pressure, and suddenly the machine would take off like a rocket. Once I got it going I could control it well, but the first few stitches of any seam or line were a little hectic. However, after working with it for three hours I began to feel good about it.

This past week I completed two small projects at home. Neither one was a class assignment, but they were both sewing projects of my own design, so I will include them in this blog. The first project, while not a class assignment, is still for class. I am pleased with the design, but the execution could have been better. It is not bad; I would just like it to be better. On the other hand, this was my first bag of this type, it is a lot more complicated than any other bag I have made, and I learned a lot while working on it, so I consider this project a success. Now that I know what I am doing with this bag design the next one I make will be a lot nicer.

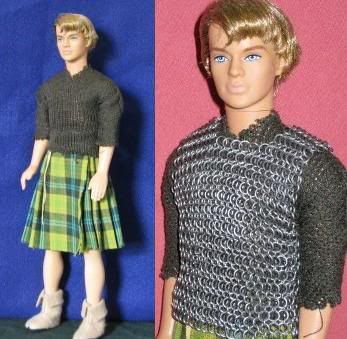

My other project combines apparel with my other design medium, chainmail. Before I provide any further details of this project there is something I must explain. I wish I did not need to state this, but at times I feel I cannot stress it enough. There is a huge difference between designing outfits for dolls and playing with dolls. I DO NOT PLAY WITH DOLLS. I have been making doll apparel for a couple years now. It is nice to be able to make a full outfit with less than one yard of fabric.

I began by dressing this fine laddie in a shirt, kilt, and pair of boots so he can look sharp while wooing the lassies. Then I equipped him with some armor in case he should need to defend his home from the English.

My homework for next week is to bring two yards of muslin to class with me. I do not know what we will be doing, but I know that we will not be working with 5” x 10” rectangles again. I am looking forward to new shapes.

Tuesday, September 8, 2009

A new sewing machine and Walmart

The real excitement happened over the course of the past week. I bought a new sewing machine. I wanted a Singer 99k, but any cheap machine that works well would do. I searched the pawn shops and thrift stores, but found nothing I liked. I could have bought a 99k on eBay, but I do not want to purchase a used machine that I have not tried first. I will eventually find a 99k, but I needed a new machine now so I bought a Brother LX-3125 at Walmart. I have been pleasantly surprised with how well it works. It is a simple machine with no bells and whistles, but simple is what I wanted.

My new sewing machine is a source of excitement and joy, but last week I learned some bad news that has left me feeling sad. Prior to the start of last week’s class some of my classmates and I were discussing where we purchased our muslin. I told them I shopped at Walmart because they have the best prices for fabrics. A few others in the class said they wanted to shop at Walmart, but their local Walmarts no longer have a full service fabrics department. I had never heard of such a thing as a Walmart without fabrics. In the past two years my Walmart shopping experience has been confined to two stores, both of which offer a full service fabrics department. After hearing from my classmates I assumed that it was just a few of the smaller stores that now do not have fabrics. But, as I was to soon learn, that is not the case. As I was searching for a new sewing machine I found myself in Bloomington where the Walmart was recently upgraded to a Walmart Supercenter. I had purchased fabrics at this store prior to its metamorphosis, and I thought that even if some smaller Walmarts no longer have fabrics a Supercenter surely will. To my great surprise and dismay I learned that not only were there no fabrics, the store did not have a crafts department at all.

I went to my local Walmart where I purchased the sewing machine along with some interfacing, and I had a long chat with the employees in the crafts department about the future of Walmart. They told me that the folks in Bentonville, AK decided to get rid of full service fabrics from all Walmart stores. Some stores protested this decision and were granted a temporary reprieve. The final fate of Walmart's full service fabrics departments has not yet been determined, but it is possible that by the end of the year they will all be gone.

Walmart is my favorite fabrics store. They do not have as broad a selection as can be found in stores devoted to sewing and/or crafts, but Walmart’s prices cannot be beat. Their prices are often as much as 25% less than those at JoAnn Fabrics. Furthermore, Walmarts are often easier to find than other craft and fabrics stores. On my one visit to Menomonie, WI, I was pleased to see that the town has a Walmart Supercenter. I told myself that after I start at UW-Stout this store will be my primary source of fabric. Now I do not know if I will be able to shop there or if I will have to go elsewhere. JoAnn Fabrics and Hancock Fabrics do not have stores in Menomonie. If the Menomonie Walmart does not have fabrics I may have to drive more than 20 miles to Eau Claire to shop.

Your help is needed to keep full service fabrics in Walmart. Tell the manager of your local Walmart how important their fabrics department is. I found this petition asking Walmart to keep their fabrics department. Please sign it and encourage others to do so to. Your assistance in this matter is greatly appreciated. Thank you.

Tuesday, September 1, 2009

Sewing machines, fabric, tools, and bags

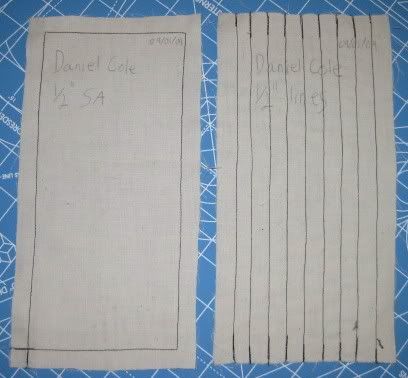

Our assignment in class today was about measuring, cutting, and seam allowances. We began by cutting 24 5” x 10” muslin rectangles. We then sewed together four pairs of them with seam allowances ranging from ¼” to 1”. The assignment concluded with a fifth pair of rectangles sewn together with multiple seams at ½” intervals. Vogue will never run an article about muslin rectangles no matter how well they were cut and how accurate and straight their seam allowances are, but making them was good practice and everyone has to start somewhere, so I am very happy with my rectangles.

In preparation for class I needed to buy some supplies. I needed bobbins and a bobbin casing for industrial machines, five yards of muslin, and some tools. The bobbins and bobbin casing were available at the campus bookstore, I bought the muslin at Walmart, and the tools I eith

er already owned or bought at Walmart and JoAnn. I have been using a Fiskars scissors for years, and few months ago I bought my first rotary cutter after I noticed some of the designers on Project Runway using them. For class the instructor highly recommended Gingher scissors. I have never had reason to complain about my Fiskars scissors, but I know the ones from Gingher are considered to be the best available, so I bought them. So far all I have cut with them is the muslin rectangles, but they seem to be great.

er already owned or bought at Walmart and JoAnn. I have been using a Fiskars scissors for years, and few months ago I bought my first rotary cutter after I noticed some of the designers on Project Runway using them. For class the instructor highly recommended Gingher scissors. I have never had reason to complain about my Fiskars scissors, but I know the ones from Gingher are considered to be the best available, so I bought them. So far all I have cut with them is the muslin rectangles, but they seem to be great.Whenever I find myself at JoAnn or in the crafts section of Walmart I am unable refrain from making a number of impulse buys. In addition to my class supplies I decided to buy fabric to make a nice bag. I went with duck cloth (my favorite fabric) for the outer shell, a heavy interfacing to give some support, and bright pink polyester for the lining. I started work and quickly discovered my sewing machine could not handle the materials. I simplified the design, removing first the interfacing then the lining, but the duck cloth by itself was still too much for my machine. I gave up on the duck cloth completely and switched to a lighter weight canvas. I attached a zipper and had just three seams left for a simple rectangular bag, and my machine stopped working at all. Without those three little seams my bag is just a flat piece of cloth with a zipper in the middle. I plan to buy a new sewing machine soon. Eventually I’ll want my own industrial machine, but that’s a few years in the future. For now I just need a basic home machine that can handle a simple straight stitch.

I found a bag in my apartment that will hold all my supplies, but I still plan to make a new one. I could bring the cut pieces to class with me to assemble them with an industrial machine, but I don’t know if I’ll have time after finishing my assignments. If I get a new machine I’ll have it finished for class next week. If I don’t have a new machine by then I’ll bring the pieces with me and hope I have the time.

Tuesday, August 25, 2009

The journey begins

This class is an introduction to sewing with an emphasis on industrial equipment. We will not be doing any design, but that’s ok. I need to learn how to use the equipment and become comfortable with it before I can do anything fancy. We will work with both straight stitch and overlock machines. Class meets on Tuesdays for 4.5 hours. The first hour or two of class will be spent in the classroom, and the rest of the time we’ll spend in the lab sewing. Our three projects for the semester are a baby t-shirt, an adult t-shirt, and a tailored shirt.

Today we spent the first two hours getting started and going over the basics: introductions, expectations, the syllabus, class info, and all the normal first-day-of-the-semester stuff. Then we went into the lab for our introduction to industrial straight stitch machines. The instructor warned us that despite a similar appearance, home sewing machines and industrial ones have very little in common. She added that after we get used to the industrial machines we’ll never want to use a home machine again.

I knew the industrial machine would be powerful, and I knew it would be a lot faster than my home machine, but I really had no idea what I was in for. Holy cow that thing is fast. All we did today was use the machine to trace lines on paper. No thread or fabric was involved. We started with long straight lines, moved on to right angles with shorter lines, upgraded to wavy lines, and finished with spirals and curves. The straight lines were a lot harder than I expected they would be. I hit the pedal, and vroom, the entire sheet has flown by with my perforations veering far from the printed line. It took some time, but I eventually got the feel for the pedal and was able to trace a line. The short lines and right angles were a little more difficult, but by the end I felt comfortable with them too. Then I hit the wavy lines. I was able to make a wavy line, but my lines and those on the page did not always match up too well. Next was a large spiral that seemed easier than the wavy lines. My final sheet combined small circles and wavy lines. I’d be lying if I said I could consistently follow those lines, but even on that sheet I noticed significant improvement from start to finish. I’ll need a lot more practice before I feel comfortable with an industrial machine, but then that’s why I’m taking this class. By the end of the semester I expect I’ll be sewing like a pro and that I’ll never want to use a home machine again.

It is still early, but I think I have already accomplished my most important goal from this class. I applied to UW-Stout in the belief that I wanted to earn a degree in apparel design, but since I have never been in any way involved in the apparel industry (buying and wearing clothes doesn’t count) I was afraid I had made a foolish choice. All we did today was talk about sewing and use the machines to put holes in paper, but I feel confident that I am in the right field. Class was fascinating and I am excited about apparel construction and design. This is just the beginning; I want to do a lot more. Even the sound of a sewing machine seems to perk me up and bring a smile to my face.

Wednesday, August 19, 2009

Introduction

I received my high school diploma in 1993. Between 1994 and 2003 I attended five colleges but never earned a degree. I majored in religious studies, physics, education, Hebrew, and emergency medical services, and I took classes in a number of other fields. I have been working full-time since 2004. I had and lost a great job; now I have a job.

In the past I did not particularly want to go to school. I enjoyed the college environment and I liked learning new things, but I never felt passionate about what I was doing and I had no desire to pursue a career in anything I studied. I went to school because it was expected of me and I was told it was the right thing to do. My ambivalence about school led to my repeated changes of majors, my failure to ever finish a degree, and ultimately my decision to stop going to school. But now I think I am finally ready to go to school and finish a degree.

I understand if my past performance does not inspire confidence in my ability to earn a degree. But I think that this time I’ll finally manage to accomplish my goals. Sixth time’s the charm? In the past I started at school, then chose a major. This time I picked the major first, then searched for a school. I will be majoring in apparel design. I have always enjoyed sewing, but I never did much with it before. I would like to become a costume designer, but fashion design looks good too.

I start at Minneapolis Community and Technical College (MCTC) next week, and I’ll transfer to UW-Stout in January. I will only be taking two classes at MCTC: Industrial Sewing Methods and Fashion Sketching Workshop. I do not expect to transfer the credits to Stout. I am taking these two classes to ease myself back into school, to prepare me for the classes I will take at Stout, and to ensure that this is indeed the field I wish to pursue before I make the move to Wisconsin.

This blog will chronicle my time in school as I progress from amateur neophyte sewer to fashion/costume designer and master tailor.