I think I did a very good job with this shirt. It is far from perfect, but I see consistent improvement with every shirt I make. I had a lot of trouble with sleeve plackets and cuffs on previous shirts, but now those two seem easy. My collar stands are getting better, but they still need a lot of work.

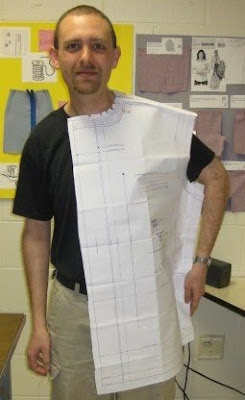

Unlike the previous two projects for my class, this one did not require a fit muslin. We did a tissue fit instead.

The torso fit well, and my pattern had neck sizes marked in inches, so those two areas presented no problems. I thought I would have to lengthen the sleeves, but after pinning my pattern to me my instructor said the sleeve length was good. I should have lengthened them. The sleeves on my first shirt were too short and I did not have enough fabric to make new ones. I was ahead of schedule, so instead of making giant cuffs I made a new shirt.

The torso fit well, and my pattern had neck sizes marked in inches, so those two areas presented no problems. I thought I would have to lengthen the sleeves, but after pinning my pattern to me my instructor said the sleeve length was good. I should have lengthened them. The sleeves on my first shirt were too short and I did not have enough fabric to make new ones. I was ahead of schedule, so instead of making giant cuffs I made a new shirt.I need an unbleached muslin shirt for my fashion industry class. My plan was to make that shirt after I finished the broadcloth one for apparel construction, but after I gave up on the broadcloth shirt I decided to use the same shirt for both classes. I used a heavyweight muslin that looks quite nice for apparel.

I am not sure where the idea came from, but at some point I found myself thinking that as much as I liked my natural color shirt I would like it even more tie-dyed. Once an idea gets lodged in my head I cannot shake it. The local stores did not have a great selection of dyes, but I think the colors I chose work well together. I am almost done with an undyed shirt for fashion industry.

Every year the apparel design instructors at my school meet with industry representatives to evaluate the program. The most recent feedback they received was that Stout graduates are skilled in the technical areas of apparel design but have difficulty with presentation, communication, and technical writing. The department will try to work on those areas. Most classes will now require students to make some form of presentation. Instead of a final exam for apparel construction, we had to make portfolio pages and present them to the class.

I never made a portfolio page before, I do not know how to use the software usually used for portfolio pages, and there was only one brief lesson in class about how to make a portfolio. My pages for this class did not have to be up to professional standards; the purpose of this assignment was to introduce us to portfolios and presentations. I included photos of the shirt, samples of fabric and notions, and flat drawings of the shirt and some of its more difficult parts. I think my instructor was pleased with my portfolio. Tomorrow I get it back and find out what I did wrong.

No comments:

Post a Comment